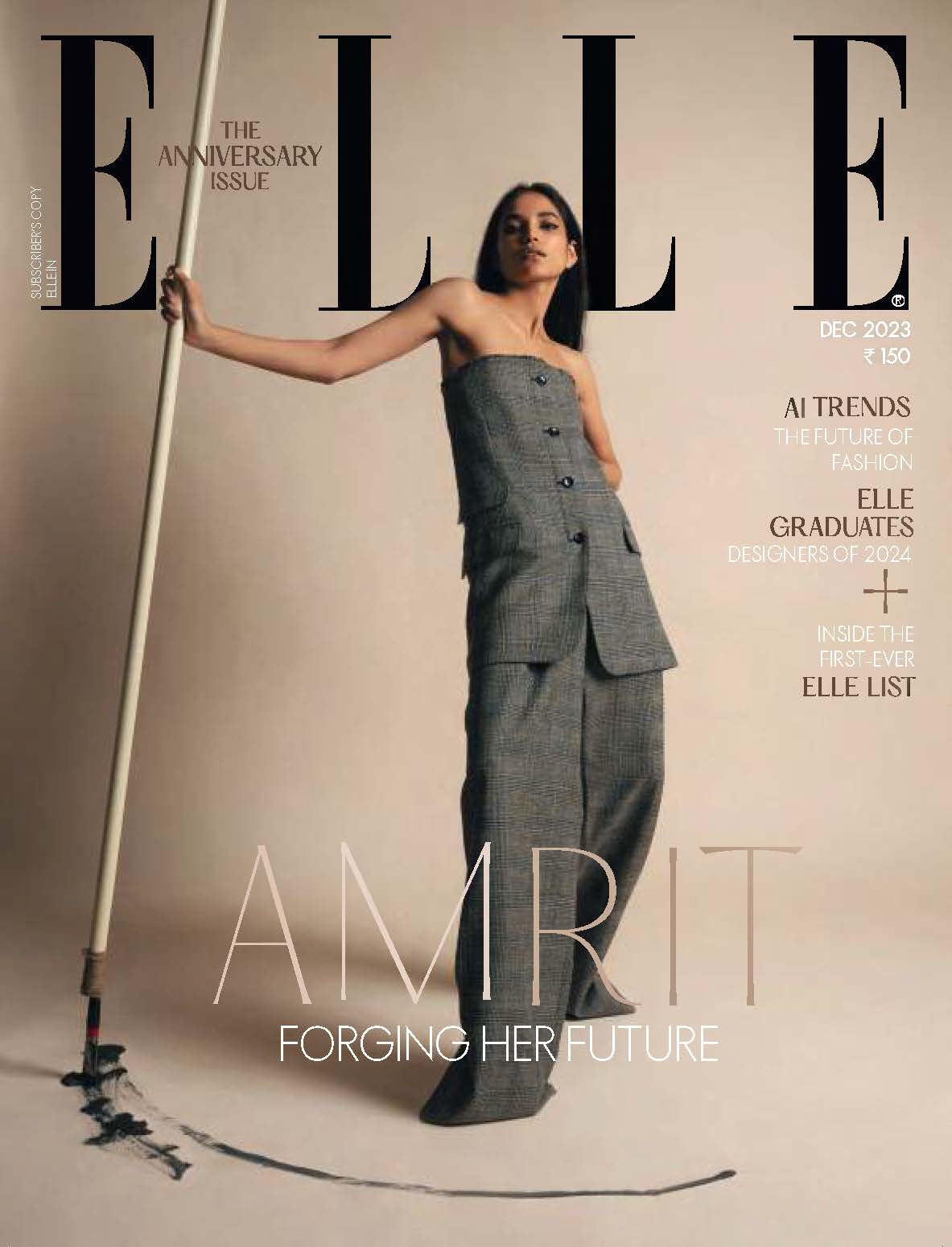

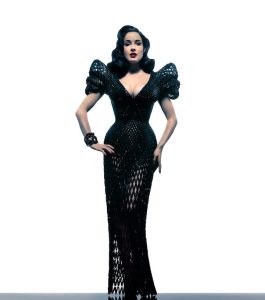

In March 2013, model and dancer Dita Von Teese appeared at a private runway show in New York to show off a single item of clothing: A fully 3D-printed floorlength gown. Created by designers Michael Schmidt and Francis Bitonti, the gown was an all-black web of nylon that from a distance looked like a plastic mesh of chainmail designed by the people responsible for one of the unfortunate pre-Nolan Batman movies. But up close it was a thing of beauty: Made from 17 parts put together by hand, it seemed crafted for Von Teese’s body, following her every curve and movement.

Much has been made of 3D-printed fashion – indeed, 3D-printed everything – in the past few years. Last summer, Mary Huang and Jenna Fizel, a pair of New York designers, introduced ‘strvct’, their line of 3D-printed shoes. The previous year, they made a 3D-printed bikini. Dutch designer Iris van Herpen has been experimenting with 3D-printed high fashion since 2010, and in February this year, another New York designer, Kimberly Ovitz, sent models down the runway with 3D-printed armour-like jewellery modelled after animal exoskeletons at New York Fashion Week.

More broadly, 3D printing is being applied to everything from building houses to producing food. But what is 3D printing? And what does it mean for the world’s fashion houses, apparel stores and neighbourhood tailors?

There can be no denying that ‘3D printing’ is certainly a very sexy term, even if it is a little vague. But then, most people would probably lose interest if they heard the words ‘additive manufacturing’. A 3D printer works in a similar fashion to your deskjet printer, but with an added dimension. Your printer reads a file – say a text document or an image – and then reproduces it line by line on a flat surface. It has no idea whether it is spitting out a bunch of words or a toothy portrait of your niece. For the printer, they are all just shapes.

A 3D printer also reads a file, made in this case with design software of the sort used by industrial designers, and then uses ‘ink’, which could be anything from liquid plastic to melted chocolate, to produce that design, one layer at a time, from the bottom up. That’s an additive manufacturing process, in that you are adding layers to make something.

One way to imagine it is as an icecream machine dispensing softees. What sits inside the machine is tightly packed, shapeless ice-cream, but what you get is a swirling tower of soft vanilla. Making a softee depends on the dispensing pressure and skill of the person handling the cone underneath it. In 3D printing, the cone is replaced by a platform and the movement comes from the nozzle, which follows set paths in all three dimensions.

The attraction of 3D printing is that it allows designers a level of complexity and accuracy unmatched by either hand or traditional mass production. It also enables them to produce things in small quantities at relatively low costs, negating economies of scale. And with the right materials in your printer, you should be able to print pretty much anything. Not for nothing has 3D printing been called a leading player in “the third industrial revolution”.

Paris, France

The implications of this technology for fashion are enormous. If – or rather when – 3D printing goes mainstream, the fashion industry is one of the first it will up-end. Over the last century, as we have grown accustomed to the advantages of inexpensive, ready-to wear clothes in a range of sizes and styles, we have also had to give up a few things, chief among them being individual design needs and perfect fits. With its scope for infinite modifications at marginal cost, 3D printing brings with it the promise of what big firms like to call ‘mass customisation’.

Take shoes, for example. A pair of running shoes is made up of several components. The basic shape stays the same, but if it were cheap enough, there is little reason for big companies not to allow customers to choose their own colour schemes, patterns and materials from within a limited range. More ambitiously, think back to Von Teese’s dress. Designers could still create one definitive item of clothing, as they do now. But instead of being shipped to China, where it is manufactured in several colours and sizes, the design would become the base from which every customer could get it modified to precisely their shape and style needs. Even the material may change – where one buyer may wear only nylon, another may find lycra more appropriate.

The attraction of 3D printing is that it allows designers a level of complexity and accuracy unmatched by either hand or traditional mass-production

There is still a long way to go before you can select and pay for a design online in the afternoon and print it out at home in the evening to wear it to a party at night. For the time being, the most commonly seen 3D printer objects are little trinkets and souvenirs – items without much practical value. The industry is limited to a handful of growing start-ups, research labs and hundreds of hobbyists trying out new things in their homes.

But it is gathering pace. In June, Stratasys, a manufacturer of industrial 3D printers, bought MakerBot, a consumer-facing firm. Staples, a big American stationery retailer, has started selling 3D printers. Some entrepreneurs are figuring out ways to make machines that retail for $200. Big manufacturers are justifiably worried about what all this means for their businesses. In fashion, they can afford to have less cause for concern. The core of any fashion business has always been its design, with production being a function of economics or marketing. With the advent of 3D printing, the latter two factors will cease to matter.

This should allow designers to focus on what they do best. And it will give consumers a renewed definition of what it means to have their own personal style – including, but not limited to – a wardrobe filled with affordable, one-of a-kind, made-to-measure fashion

HOME TRUTHS

Tech-savvy Indian designers weigh in

“3D printing is a very intense method, which requires intricate construction. The process is time-consuming but the end result is unique and beautiful. [However] the placement of the print is important. If it is used cleverly to suit a woman’s body, then it can look very flattering.”

– MANISH ARORA

“Economically, 3D printing is still a very expensive technique because it needs a high level of expertise to execute the required design. In India, we hardly have any companies with that kind of expertise.”

– AMIT AGGARWAL

“3D printing requires absolute precision and inputs from a technical professional, like an engineer, to achieve desired results. In India, a watered-down version of the trend is popular, in which digital printing techniques are used to replicate 3D images on a fabric to give the illusion of 3D design.”

– ALPANA & NEERAJ

“The most exciting part about 3D printing in fashion is customisation and the ability to convert couture into prêt. An idea that earlier would take intense labour to create can now be digitised and created with customer specifications. Not only does it then become hanger-friendly but also perfectly enunciates a design ideology.”

– ANAND BHUSHAN